Contents

01 . What is digital dentistry?

02 . Why switch from traditional dentistry to digital dentistry?

03 . The 3 main advantages of digital dentistry

04 .The advantages of digital dentistry for the dentist

05 . The advantages of digital dentistry for the dental technician

06 . The advantages of digital dentistry for the patient

08 . SCAD-CAM software: what they are and what they are used for

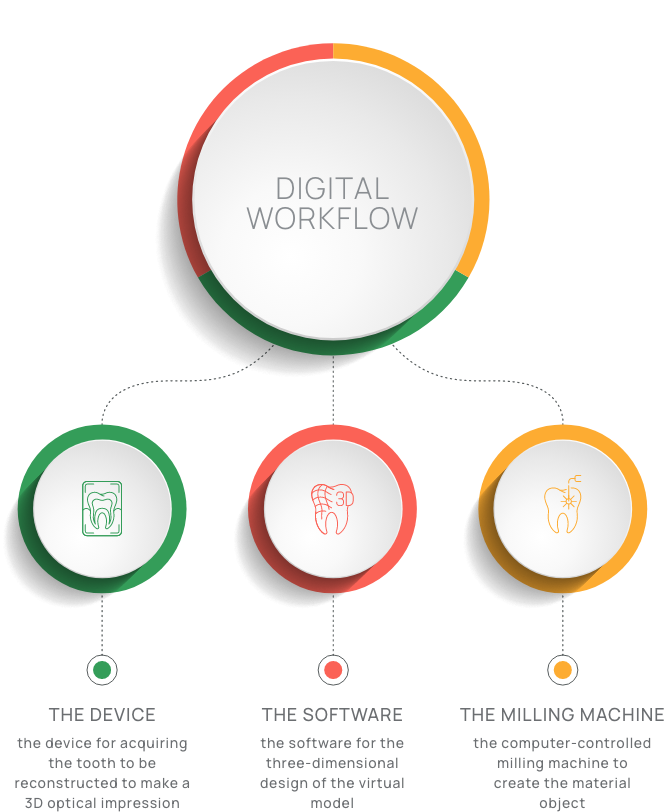

What is digital dentistry?

In short, the data acquired endorally, thanks to the digital instrument, are converted into a 3D model and sent to the computerized grinding machine. With this method, therefore, the traditional impression is no longer necessary, except in certain cases.

Why switch from traditional dentistry to digital dentistry?

As we know, digital technology has changed our habits in many areas, both in our private and professional lives. It has created new markets and offered opportunities to improve the business of millions of companies worldwide.

In particular, those companies and professionals that were most reluctant to change were the ones who felt the brunt of the digital revolution. However, those who have been able to see the benefits of this transition have been able to evolve their business to adapt it to the new reality. Many of the first ones had to succumb to more efficient competitors that had adapted to follow the course of digital evolution.

In this respect, dentistry and dental technology are no different from many other disciplines or types of business. For this reason, the evolution towards digital cannot be considered as an optional choice, but rather as a compulsory route for any professional who wishes to remain competitive in an ever-changing scenario.

We did not write the word competitive by chance. The point is this: digital dentistry is more efficient than traditional dentistry carried out with classical procedures and analog instruments. This means that, over time, all those who will be entering the profession for the first time will be induced to embrace the digital method, without even considering the possibility of resorting to previous dentistry methods, except perhaps for a few ‘niche’ activities. That is why it would be advisable for those who have been working in this field for some time to evolve and welcome the advent of digital technology.

The figures emerging from a survey carried out by iData Research are significant. This survey estimates that by 2021 the European digital dentistry market will be worth €578.7 million. Furthermore, the same research points to a fact: the growing demand for better infection control offered by CAD-CAM and 3D printing technologies with the onset of the pandemic has driven the transition to digital.

In any case, the end of the pandemic will not stop the growth of the sector, so much so that iData Research predicts that the digital dentistry market in Europe will further increase its value to reach €1.4 billion in 2027.

Beyond the numbers, it is clear that digital dentistry is the near future for professionals engaged in this market every day.

The 3 main advantages of digital dentistry

These innovations allow the digital dental practice to stand out from the competition and offer its patients a more effective type of dentistry.

As mentioned above, the use of digital tools makes it possible to reduce the risk of error, often due to the human factor, resulting in a more accurate result in less time.

In particular, 3D intra-oral scanning provides more accurate data, which is useful in the tooth modeling phase. Added to this is the fact that CAD-CAM software for dental work has user interfaces that reproduce traditional workflows, with the possibility of automating certain stages and identifying and correcting errors easily.

Once the three-dimensional model of the tooth has been completed, tools such as 3D printers and milling machines make it possible to produce a tailor-made finished product of excellent workmanship, with a better fit and reproducible in a short space of time.

All this helps to improve clinical outcomes, for the patient and the dentist.

Lastly, the positive impact of digital dentistry on the environment should be mentioned. Optical impressions and 3D printing using the additive method save a considerable amount of material and, as a result, produce less waste than traditional techniques.

The advantages of digital dentistry for the dentist

Inoltre, grazie alle stampanti 3D, gli studi odontoiatrici possono realizzare prodotti semplici in autonomia, come dime chirurgiche, ferule, modelli diagnostici e progettazioni del sorriso.

Do you want to know how to improve the work in your practice with digital dentistry? Sign up for Dentitudë now. You will have access to a range of exclusive content designed for dental professionals.

The advantages of digital dentistry for the dental technician

For example, thanks to digital technology, the prosthetist can receive an impression immediately from the dental practice. It is only a matter of sending a file, no longer a physical object.

In addition, the accuracy of this impression is remarkable, eliminating any possible subjective interpretation by the technician. The risk of error is greatly reduced.

All this translates into an increase in the speed of work for the prosthetist, who will be able to make the prosthesis in less time and with greater precision. In other words, his productivity improves considerably.

If a dental laboratory is willing to work with digital dental impressions, it eliminates the long lead times involved in shipping physical models. In this way, the laboratory can serve its customers in a wider geographical area or specialize in the manufacture of certain products.

When it comes to materials, digital techniques offer a greater variety of choices than traditional methods. In this case, the use of the correct material has to do with the chosen 3D printing procedure, whether by subtraction or addition. Most often, these are aesthetic materials, such as:

The advantages of digital dentistry for the patient

We have already highlighted the fact that digital dentistry instruments allow impressions to be made with far greater accuracy than analog techniques – for example, they can detect gum tissue and tooth contours.

This advantage also creates a benefit for the patient: thanks to digital instruments, it is possible to eliminate the use of impression pastes, which often cause nausea.

Digital workflow in dentistry: what is it and how does it differ from analog (traditional) workflow?

Workflow is a concept that applies to all kinds of activities, including those of dentists and dental technicians. To summarize, workflow can be defined as the set of tasks required to carry out an operational or work process.

In this sense, it does not matter if you practice different dental specialties – general dentistry, implantology, prosthodontics, or orthodontics.

Treatments and instruments indeed vary according to the specialty practiced and the application required. However, they all follow the same workflow. Let’s see why.

As in traditional dentistry, which is carried out with analog instruments, digital production always involves, as a first step, the patient’s anatomy. In this sense, therefore, intraoral 3D scanners are a useful device for scanning the teeth, quickly and with a much higher degree of precision than can be achieved with any classic method.

The alternative is optical desktop scanners in dental laboratories, capable of scanning traditional impressions or plaster models.

A CBCT (Cone Beam Computed Tomography) scanner can be added to the 3D scanner, which is useful for treatments and applications requiring osteotomy of the patient.

Once the scan is complete, the patient’s anatomical data are imported into the dental CAD software. In this second phase, treatment planning and the design of prostheses, models, and mock-ups are carried out. This software reflects traditional working methods: it has intuitive interfaces, equipped with tools familiar to technicians, such as virtual articulators.

In this way, results can be achieved in less time and more accurately. In addition, after design, models can be exported for production; if changes are needed, it is enough to work on the original file without having to create a new model.

The third stage involves making the dental product from the digital model. In this case, the 3D models are loaded into CAM software and sent to a 3D printer or a milling machine.

3D printers can create a wide variety of products, including dental models, surgical templates, dental splints, retainers, wax-ups, dentures, and castable models. Layer by layer, the printer shapes dental models with an unparalleled degree of definition.

The use of digital technologies simplifies the workflow between the dental surgery and the dental laboratory: quicker communication, ease of use, and cost optimization are some of the advantages of this method of working.

What happens in the traditional workflow? In this case, the dentist has to make a physical impression of the patient’s teeth. The impression has to be delivered to the dental laboratory. At this point, the technician has to make the model, prosthesis, or other application. The product then has to be sent to the dental office, so that the planned treatment can be performed.

With digital workflow, everything is faster and more efficient: information exchanges between the dental practice and the dental laboratory can take place in real-time, which reduces the waiting time for the patient that is typical of analog workflow.

What’s more, thanks to digital technology, the dentist gains several advantages:

CAD-CAM software: what it is and what it is used for

cad

cam

cnc

In this case, at least one step in the dental laboratory is required. More specifically, the patient’s data can be processed by the dentist, to perform CAD, or it can be sent to a dental laboratory in real-time. In this scenario, communication between the practice and the laboratory is immediate. This speeds up the delivery time of the finished object, according to the specifications shared in real time.

The indirect method involves making an impression in the traditional way, by hand. The impression is then sent by the dentist to the dental laboratory. This means that the process steps of digital capture, data processing, and object fabrication take place elsewhere than in the dental office.

The limits of digital dentistry

Having taken a close look at the advantages of digital technologies, it is now time to learn about the limitations of this new approach to dentistry.

Those most skeptical of the digital transition fear a future populated only by increasingly sophisticated machines, in which the role of the professional will be secondary or even no longer indispensable. These are science-fiction scenarios that are hardly compatible with reality. A complete transition to the digitalization of all dental techniques will not take place even in the years to come. On the contrary, several sensitive procedures will still involve the use of traditional, analog instruments.

This means that there will still be a need for trained professionals capable of carrying out complex manual operations and checking the result, both from the point of view of effectiveness and aesthetics – all tasks that a machine cannot perform properly.

In summary, digital technologies in dentistry are – and will increasingly be – a valuable aid to the daily work of dentists and dental technicians. Digital tools are aids for professionals called upon to carry out precision and routine work, fields in which machines and software can contribute productively.

The manual touch, the creative solution, and the evaluation, aesthetic and medical skills are prerogatives that are – and will remain in the coming years – exclusive to professionals who are attentive to continuous training, the improvement of their skills, and the intelligent use of new technologies to achieve better results with less effort and in less time.

Dentitudë exists precisely for this reason: to offer concrete support and training resources to all dental and dental technology professionals who wish to embrace the digital transition.

Conclusions

As we have seen, when applied correctly, digital technology provides significant advances over the traditional way of working.

These benefits extend to everyone involved in a typical dental practice.

In particular, dentists and dental technicians can work better, with more precise results and in less time, which benefits their productivity.

What’s more, the patient no longer has to undergo endless, repeated sessions. And everyone knows that a more satisfied customer can become an effective word-of-mouth vehicle for any dental practice.